If you haven’t explored custom products, you’re probably paying more than you need to. While purchase decisions based upon price alone will frequently prove more costly in the long-run, custom products are a value you should really be considering.

What are custom products? What are white label products? How does this all work and how can they be less expensive than a standard product? We’ll cover those questions and more below, but here’s the bottom line: custom products require planning and commitment on your part, which translates to guaranteed purchase quantities for manufacturers and distributors. We like that. It results in zero product waste. It reduces our inventory risks. It makes planning and forecasting easier. In short, it makes the product less expensive to us, therefore less expensive to you.

First, what are white label and custom products?

White label is simply the practice of taking a standard product and putting a different label on it. In retail, this is common but less transparent. You’ve undoubtedly purchased white label products without realizing it. Sometimes it’s obvious. Kirkland brand items are white labeled and sold by Costco, and they make little attempt to disguise the fact. Manufacturers are happy to sell their products at a discount for white label use because 1) guaranteed purchase quantities, and 2) while you know Kirkland is white label, you don’t know the original brand (which is important in retail to protect brand pricing).

Custom products, at least as it relates to this article, are white labels with some tweaks. This is most common in product bundles, like IV start kits or dressing change trays. Because the label is being customized, what goes in the box can be customized as well. Don’t like that blue tourniquet? Want the green one? No problem. Need two pairs of gloves instead of one? Sure thing. This can be as simple or as complex as you need, however, replacing normal items with far more expensive items will eat into those savings.

What goes into a custom product agreement?

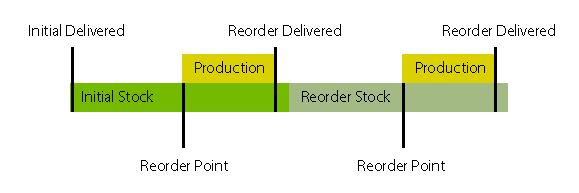

Most importantly, you need a good understanding of your usages. Your distributor will be working with the manufacturer to develop production schedules, inventory levels, reorder points, and reorder quantities. Over time this can be adjusted, but it’s best to get as close as possible to start. Based upon this information, you’ll be asked to agree to 3 things:

1. Initial order quantity – the number of units ordered for initial stock.

2. Reorder point – based upon manufacturer lead times, at what point a new order needs placed to ensure continued product availability.

3. Reorder quantity – the number of units ordered once the reorder point is reached.

What’s the risk of custom products?

We’ve covered the two primary benefits; lower cost and ability to customize contents, but you also need to consider the risks. Actually, there is just one. From the moment an order is placed with the manufacturer, whether initially or at a reorder point, you are committed to purchasing all of the products.

Where do you go from here?

Identify some potential opportunities for custom or white label products. Look for commodity type products with stable usage, particularly bundled products. Then contact your distributor to start the conversation!

This is a valuable service that many customers don’t know about. It’s a great opportunity to use the relationship with your vendors to learn how they could be providing more value. Right Way Medical has significant experience consulting on custom product agreements and would love to help. Contact us today to learn more.